NEW PATENT – CLAMPING FIXTURES

This patent refers to clamping fixtures designed for measuring plastic or metal components. Specifically, it addresses the adjustment of the component’s fixing points on the fixture to ensure the accuracy and precision required by the design.

The solution was developed to optimize dimensional inspection processes and, compared to traditional steel or aluminum fixtures, offers reduced production costs and lead times, along with a weight reduction of up to 80%. The fixtures are manufactured using a hybrid approach: FDM 3D printing for the main structure and resin 3D printing for the fixing points, which are the core focus of the patent.

The patent targets all industries that use plastic or composite material components – including automotive, medical, and aerospace sectors.

The solution was developed to optimize dimensional inspection processes and, compared to traditional steel or aluminum fixtures, offers reduced production costs and lead times, along with a weight reduction of up to 80%. The fixtures are manufactured using a hybrid approach: FDM 3D printing for the main structure and resin 3D printing for the fixing points, which are the core focus of the patent.

The patent targets all industries that use plastic or composite material components – including automotive, medical, and aerospace sectors.

A SYNERGY OF METROLOGY, DESIGN, AND 3D PRINTING

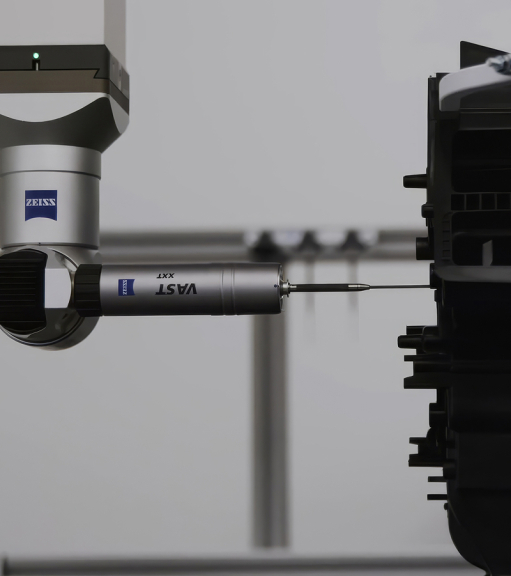

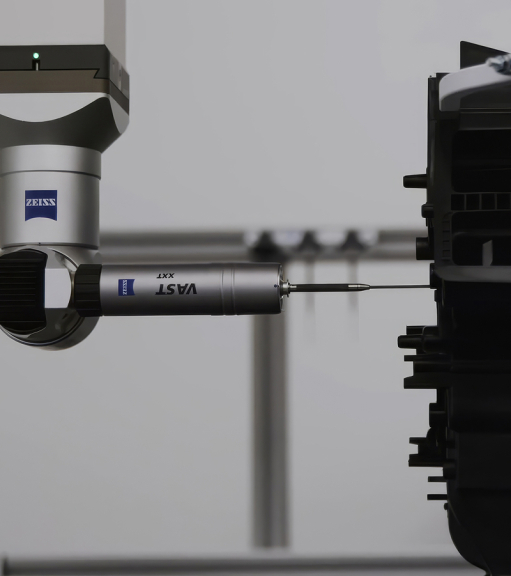

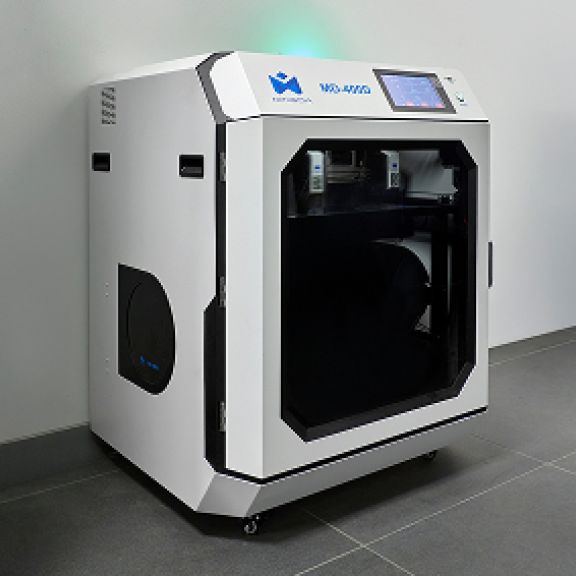

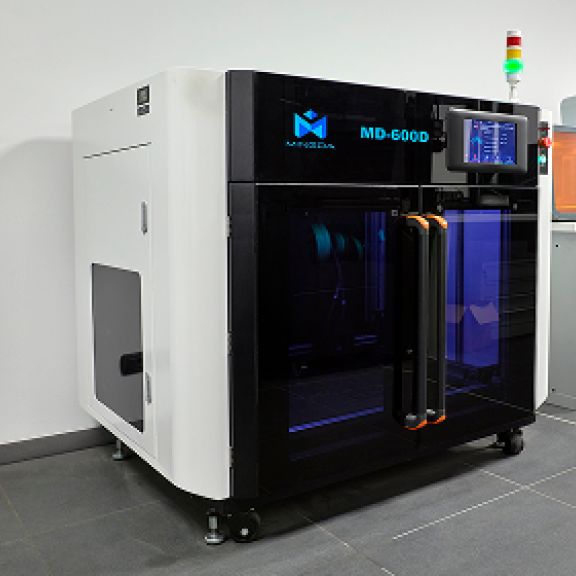

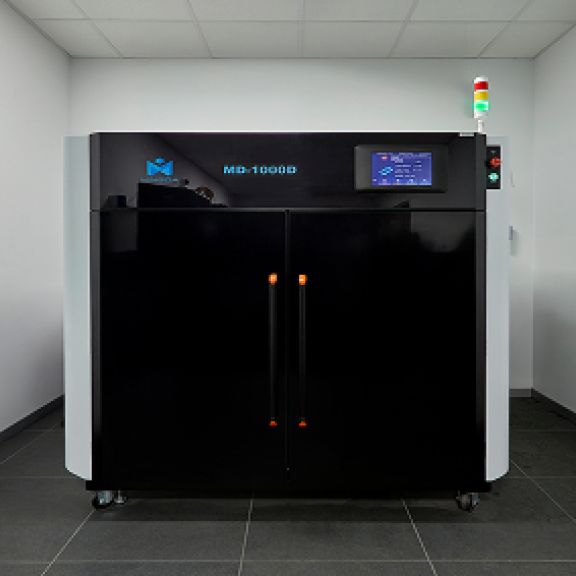

To produce these fixtures, we use advanced CAD software for design, large-format 3D printers with capacities up to one cubic meter, and coordinate measuring machines (CMM) for certification. Many of our clients already use our fixtures in daily operations and have fully replaced their traditional metal fixtures.

ADVANCED TOOLS

3D PRINTER MD400

3D PRINTERS MD600

3D PRINTERS MD1000

CMM ZEISS PRISMO 12 18 10

SUSTAINABILITY

Another key advantage of our fixtures is their environmental friendliness. The materials used in the compound include renewable resources derived from corn, which help reduce environmental impact during production and allow for easy recycling in case of disuse or print errors. Furthermore, the 3D printers used are more energy-efficient than conventional CNC machining centers.